|

Once in a while, a

tool comes along that really makes your life easier, especially when it helps

you out with a task that you're not particularly fond of. For many years,

I had a sort of aversion to using photoetch parts, just for the simple fact that

they can be difficult to work with. Granted, they do add a new dimension

to modeling, but sometimes, trying to bend a flat, small piece of metal into

complex, convoluted shapes can be a nightmare.

This is particularly

true with small parts. Recently, I was working on some of the Flightpath

photoetch parts for my A-10 project, and some of these parts are REALLY

tiny. Not wanting to lose any of these delicate parts, I had them taped

down to my workbench while trying to bend them with a knife blade and a metal

straightedge. The results of these parts was rewarding in terms of the

detail that they added, but it was also nerve wracking trying not to lose any of

them in the process!

As things happen, I

went out to the mailbox the same day, and what do I find, but a "Hold

and Fold"

photoetch tool. Being very anxious to try it out, I opened the box and

headed back to the cellar. The results were outstanding. I could now

shape small parts with ease, and the toolhead kept everything in place without

any fear of losing parts. Even really small parts were no problem to

shape. The toolhead has a number of smaller areas on the reverse side

which allow you to get into really tight spots to bend small parts, which worked

out great.

|

|

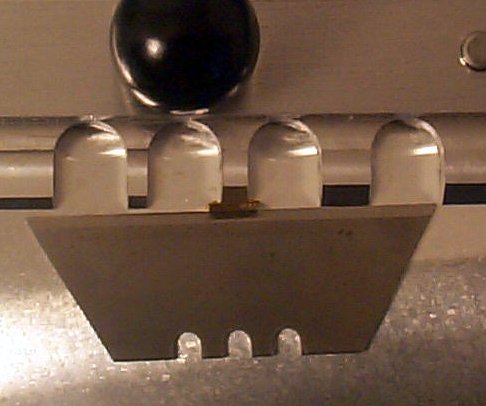

The toolhead can be reversed to accommodate

tiny parts. |

Basically, it works

like this: the toolhead screws down over the part to be bent, and locks it

in place on top of the 'table' area of the tool (which is a minutely grooved,

non-skid surface). The supplied razor is then slid underneath the part and

bent to the desired angle. When you're done, unscrew the toolhead, and

remove the part - that's it. It's that simple. I've been testing

this tool for several weeks now, and I haven't found a photoetch part yet that

couldn't be easily manipulated by the "Hold and Fold".

|

|

A close-up of the toolhead. |

If you have any

problems working with photoetch, I highly recommend this tool - to me, the "Hold

and Fold" is to photoetch what liquid cement was to styrene kits years ago. I

just can't say enough about it, and has really turned me around in terms of my

former aversion to etched parts. The only downside at all is that the tool

is a little expensive, but this is the type of tool that you'll only have to buy

once - it's construction is very sturdy, and should last you through several

lifetimes of modeling!

|

|

A ten second job with "Hold

and Fold"! The Flightpath 1/48 A-10 HUD. |

I'd like to

sincerely thank The Small Shop for providing this review sample, and I encourage

you to visit their site by clicking on their link below. Their mailing address

is:

Kalama Precision Machine is The Small Shop

PO Box 580

Kalama WA 98625

Phone: 360-673-1255

--------------------------------------

Comments about the "Hold and Fold" from

Steve

Bamford

Well, I must admit to being quite

impressed by quality of this tool. It's is made from machined aluminum and

it's plain to see the creator and manufacturer of this tool has a very good

understanding of machining metal. The edges are VERY crisp...almost sharp

and this produces a level of exactness that all modellers crave. I have

done my fair share of Photo Etched and I've always be disappointed by not

bending parts where I wanted to as well and the bends being less than sharp or

square. Then the final insult is for the part to launch itself across the

room to be lost in the carpet forever. I had heard of the "Hold

and Fold", but I had serious doubts.....obviously it can't be as good

and useful as everyone says.......well darn it all.....it actually is as good

and as necessary as everyone says....probably more so. One feature that

grabbed my attention is a spring that's installed under the top plate.

After you bend your PE part....you unscrew the knob on top and the top plate is

gently lifted by the spring to carefully reveal your freshly folded part.

Without this spring, you'd be struggling to lift this plate to remove your part

without your part landing in the carpet below your modelling desk. But

this spring saves you all that grief and is a perfect example of the attention

to detail and thought that went into this tool. The all metal construction

means this tool will last much much longer than me.....even the knob on

top....although not metal...does have a brass sleeve inside to make sure the

threads inside the knob don't stress and crumble over time with use. This

is a very high quality tool and a must for anyone that's serious about using

Photo Etched parts to dress up their latest kit.

You will also find a couple of

complimentary products for working with Photo Etched parts at The Small Shop

website.

Steve Filak, Sr.

|